Take Tooling to the Next-Level Performance with TiN Coating

Titanium nitride (TiN) coating is wear resistant, inert and reduces friction. Use it on cutting tools, punches, dies and injection mold components to improve tool life two to ten times, or more, over uncoated tools.

Medical device manufacturers use TiN coating to reduce galling between sliding components, help retain sharp edges on surgical instruments, and differentiate their products from the competition.

If you are serious about improving your manufacturing operations, coating your tools with titanium nitride is a good place to start.

TiN coating is easily stripped from tool steels. This makes TiN an ideal coating for applications that use expensive tooling such as injection molding and forming.

TiN Properties

Thickness: .0001″ – .0002″ (2 to 5 microns) on the working surfaces.

- There is some variation in coating thickness across tool surfaces. Edges collect more vapor, so they get more coating.

- Factors such as process parameters, tool geometry, tool location inside the vacuum chamber, etc., can all influence how thick the coating is on a particular area of the tool.

- It is possible to build up coating thickness by coating a part multiple times. As the coating gets thicker, there is a greater chance of spalling.

Hardness: 2400 – 2600 Hv (>80 Rc).

- This Vickers Hardness correlates to a hardness considerably above 80 Rc. (Rockwell C is not used above 80 Rc (1850 Hv)).

- Harder than Carbide.

Inert and Stable – TiN coating does not react with most materials and doesn’t begin to oxidize until about 850°F

Biocompatible – TiN coating does not react with tissue, blood, bones, or bodily fluids, making it suitable for medical, dental and food applications.

Coefficient of Friction (COF) is dependent on the type of material the coating is rubbing against; it is about 0.6 for steel alloys.

Deposition Temp. 700 – 800°F – We coat most parts at about 800°F (425°C). This temperature may adversely affect some materials. We recommend consulting with us, or your local heat treater, should you have any material concerns. This page provides additional information.

- Parts can be coated at lower temperatures, but this requires process modifications that can adversely affect coating properties such as adhesion and cycle time.

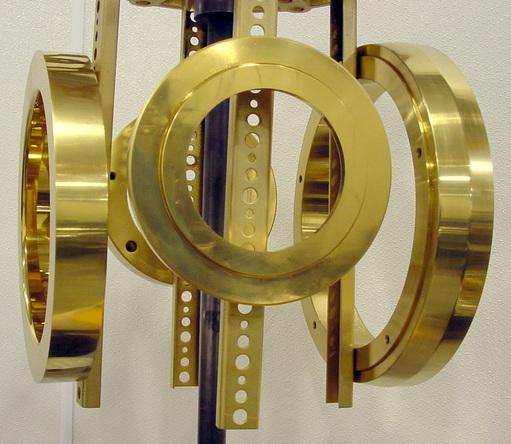

Appearance – dark gold

Adhesion – Excellent adhesion as long as substrates were properly cleaned and coating process properly executed.

Removing (Stripping) TiN – This can be done chemically with little, to no, degradation to the tool surface, but only on steel alloys (stainless, tool steel, etc.).

- We can not strip TiN from carbide and some other materials because the chemical used attacks the cobalt binder or the substrate material.

- Stripping cost is approximately 40% of the coating cost.

- TiN coating.

Case History #1

Micromachining with .018 TiN-Coated Carbide End Mill

- Workpiece: 303 Stainless Steel

- Tip Breaks @ Failure

- Results:

- Uncoated (@ 30,000 rpm): 25 – 50 parts

- Coated (@ 60,000 rpm): 100 – 200 parts

- 4x Tool Life @ 2x the Machining Rate

- Save 3 of 4 Tool Changes

- Eliminate 3 of 4 First Article Inspections

- Coating Cost – $2.00 per tool

Where to Use TiN

Cutting Tools

- All-purpose coating that significantly improves tool life by 2 – 7x over uncoated tools.

- Can be applied to all types of tools, including drills, taps, end mills, reamers, inserts, dovetails, etc.

- Materials that can be coated include HSS, M2, M4, T15, tool steels, carbide, stainless steels and other materials.

Punching and Forming Tools, Stamping Applications

- On punches, TiN provides 2 to 10x tool life over uncoated punches.

- In forming applications, TiN improves tool life and lubricity, reduces friction, and reduces, or eliminates, galling.

Injection Molding

- TiN-coated mold components last 2 – 8x longer than uncoated.

- Improves lubricity and part release for faster cycle times.

- Provides abrasion resistance when using glass-filled plastics.

- Improves corrosion resistance when corrosive gases are formed in the molding process.

- Reduces, or eliminates, galling between sliding mold components.

Medical Components

- Biocompatible, FDA approved for use on medical and dental devices.

- Use TiN for edge retention on surgical instruments.

- Improve device aesthetics to differentiate products from those of competitors.

Wear Components

- Use TiN to extend the product life, improve performance and enhance the appearance of a product.

- Typical applications would be firearm components, knife blades, bicycle parts, etc.

Aerospace Applications

- Reduces wear and galling, extends component life.

- AMS 2444A is the aerospace specification for TiN coating.