Five PVD Coatings to Improve Productivity!

PVD coatings are much harder than the base materials they are applied to. They are also inert and do not react with materials they come into contact with. This combination of being hard and inert reduces the friction between the tool and the workpiece and can result in tools lasting up to ten times (10x) longer, or more, than uncoated tools.

FAQs About PVD Coatings*

Applying a PVD coating to cutting tools as well as medical devices can offer functional advantages for both applications. Surface Solutions owner, Michael Schultz, explains everything you need to know.

*Published by Production Machining, a media brand that covers advanced new technology, practices, and processes in the manufacture of precision machined parts in high volumes.

Check out the PVD Coatings Surface Solutions Offers

Alpha™ Coating

Alpha™ is an extremely hard, all-purpose, multi-layered coating that has ZrN as the top layer.The bulk coating is much harder than its individual components. This synergy results in exceptional abrasion resistance and lubricity. Alpha™ outperforms most other PVD coatings in cutting tool and punching applications and provides 2 – 4x the tool life over TiN coatings.

Alpha™ is an extremely hard, all-purpose, multi-layered coating that has ZrN as the top layer.The bulk coating is much harder than its individual components. This synergy results in exceptional abrasion resistance and lubricity. Alpha™ outperforms most other PVD coatings in cutting tool and punching applications and provides 2 – 4x the tool life over TiN coatings.

Uses: Cutting Tools, Punches and Dies, Wear Parts, Blades, Medical Components

TiN (Titanium Nitride)

Titanium nitride was the first general-purpose coating. It’s been around for a long time for one simple reason, . . . it works. Whether it’s cutting tools, punching or forming, or injection molding, users know they are going to get anywhere from 2 to 10 times the tool life by using this coating. TiN is the coating of choice for medical applications.

Titanium nitride was the first general-purpose coating. It’s been around for a long time for one simple reason, . . . it works. Whether it’s cutting tools, punching or forming, or injection molding, users know they are going to get anywhere from 2 to 10 times the tool life by using this coating. TiN is the coating of choice for medical applications.

Uses: Cutting Tools, Punches and Dies, Wear Parts, Blades, Medical Components

AlTiN / TiAlN (Aluminum Titanium Nitride)

AlTiN is the coating of choice for high temperature applications. The aluminum in the film converts to aluminum oxide as the coating heats up, resulting in great oxidation resistance. Use this coating in your most demanding cutting tool applications and other applications where a lot of heat is generated.

AlTiN is the coating of choice for high temperature applications. The aluminum in the film converts to aluminum oxide as the coating heats up, resulting in great oxidation resistance. Use this coating in your most demanding cutting tool applications and other applications where a lot of heat is generated.

Uses: Cutting Tools, Die Cast Tools, Medical Components

CrN (Chrome Nitride)

Chrome nitride shines in heavy-duty forming applications. We’ve had customers that were polishing their dies every 300 to 500 hits that now get 25,000, or more, without touching their dies. CrN is very tough and has excellent lubricity.

Chrome nitride shines in heavy-duty forming applications. We’ve had customers that were polishing their dies every 300 to 500 hits that now get 25,000, or more, without touching their dies. CrN is very tough and has excellent lubricity.

Uses: Stamping (Forming) Tools, Medical Components

TiCN (Titanium Carbo-Nitride)

Adding carbon to a TiN film increases the hardness by nearly 80%, resulting in 2 to 3 times the tool life over titanium nitride. For improved performance and longer tool life, try TiCN in punching, injection molding, and cutting tool applications.

Adding carbon to a TiN film increases the hardness by nearly 80%, resulting in 2 to 3 times the tool life over titanium nitride. For improved performance and longer tool life, try TiCN in punching, injection molding, and cutting tool applications.

Uses: Cutting Tools, Injection Molds, Punches, Form Tools

Other Coatings

We continue to do research on additional coating materials, including nano-layered films and carbides, and will offer these materials when (if) they become economically feasible.

If your company has a need for a coating not shown here, give us a call. We may be able to provide it for you, or refer you in the right direction.

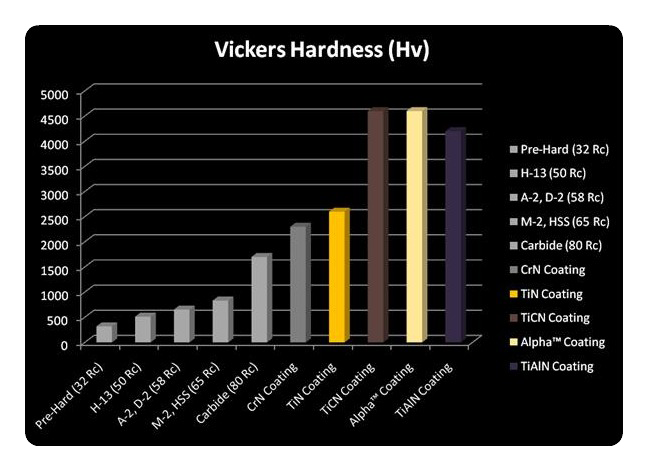

Coating Hardnesses

The chart to the right shows the approximate hardnesses of our coatings compared to some common tool steels and carbide. Please note that these numbers are only approximate for hardnesses above 70 Rc (1075 Hv) since Rockwell C testing is not done above that hardness.

All five of our coatings are significantly harder than carbide, with TiN and CrN being in the 2200 – 2700 Hv range; and Alpha™, TiCN and AlTiN being in the 3600 to 4600 Hv range.

Due to the differing hardnesses and other intrinsic properties, the premium coatings (Alpha™, TiCN, and AlTiN) usually provide longer tool life than TiN. CrN is the toughest coating, which allows us to apply a thicker coating which counteracts this coating being slightly softer.

Other Things to Know About Our PVD Coatings

- Coating Uniformity – We orient parts inside the vacuum chamber so that the working surfaces are in a direct line-of-sight with the vapor source. Areas further away from the vapor source, or somewhat hidden from a direct line-of -sight, receive a thinner coating. Flat surfaces will receive a slightly thinner coating than edges.

- How parts are held in the vacuum chamber is largely determined by what surfaces are important to the tool’s function, the goal being to expose the functional surfaces to a direct line-of-sight with the vapor source.

- Masking of Surfaces – Where parts are held usually results in that area being covered by some type of sheet metal, sleeve, or by a wire. Covered areas do not get coated.

- Irregular surfaces can be masked by applying thin, vacuum-compatible materials to a surface and then removing those materials following the coating process.

- Materials that can be coated – We can apply TiN coating to a broad range of substrates, including tool steels, stainless steels, carbide, titanium alloys, copper alloys, and nickel alloys. It is possible to coat other materials with specialized coating parameters.

- Aluminum and copper alloys can be PVD coated if there is an intermediate plating of nickel or chrome. Whether or not we would be willing to coat these types of parts would depend on the quantity to be coated per batch and the customer’s willingness to pay that batch price.

- Removing (Stripping) TiN – This can be done chemically with little, to no, degradation to the tool surface, but only on steel alloys (stainless, tool steel, etc.).

- We can not strip TiN from carbide and some other materials because the chemical used attacks the cobalt binder.

- Stripping cost is approximately 40% of the coating cost.

- Surface Finish – TiN will replicate the finish of the part that is placed into the vacuum chamber. The coating is very thin, but it does not make a surface smoother. If you want a shiny finish, you need to start with a shiny finish.

- Many coated parts end up slightly rougher than when they were put into the vacuum chamber. This is due to the presence of “macroparticles”, tiny droplets that are incorporated into the film during the cathodic arc process. This “roughness” can be removed by post-coating buffing or polishing.

- The surface finish you provide might not be the surface finish you get back. In the process of cleaning your parts, we may need to employ other processes (bead blasting, polishing, tumbling, etc.) to ensure the surface to be coated are clean. These processes can change the surface finish.