Physical Vapor Deposition (PVD) Coating Offers Many Benefits When Applied to Medical Instruments

Enhanced Hardness and Wear Resistance

PVD coatings significantly increase the hardness of medical instruments, making them more resistant to wear and abrasion. This helps surgical tools maintain sharpness and durability over time.

Improved Corrosion Resistance

Medical instruments are often exposed to bodily fluids and harsh sterilization processes. PVD coatings provide a protective layer that enhances corrosion resistance, preventing the formation of rust or other forms of corrosion. This is crucial for maintaining the integrity and hygiene of the instruments.

Biocompatibility

PVD coatings are biocompatible, meaning they are well-tolerated by the human body. This is essential for medical instruments that come into direct contact with patients during surgical procedures. The coating ensures that there is minimal risk of adverse reactions or infections.

Reduced Friction and Adhesion

PVD-coated instruments and components have lower friction levels, resulting in smoother and more precise movements during surgical procedures. PVD coatings also reduce or help prevent the sticking of tissues or other materials to the instrument, contributing to improved functionality.

Stainless steel parts that used to gall and freeze up during robotic surgery can now function over prolonged periods of time with no fear of seizing up.

Aesthetic Appeal

PVD coatings can be applied in various colors, improving the appearance of medical instruments. This not only enhances the look but also allows for easy identification and differentiation of instruments in a medical setting.

Temperature Resistance

PVD-coated instruments can withstand high temperatures, making them suitable for autoclaving and other sterilization methods commonly used in healthcare settings. This ensures that the instruments remain sterile and ready for use in medical procedures.

Increased Lifespan

The enhanced durability and resistance to wear and corrosion contribute to a longer lifespan for medical instruments. This results in cost savings since fewer replacements are needed. PVD coatings can result in up to 10x the life over uncoated instruments.

Precision Coating Thickness

PVD processes allow for precise control over the coating thickness, ensuring uniformity and consistency. This level of precision is important for maintaining the desired properties of the instruments without compromising their performance. In summary, PVD coatings offer a range of benefits that make medical instruments more durable, corrosion-resistant, biocompatible, and aesthetically appealing, ultimately contributing to improved functionality and hygiene in medical settings.

In summary, PVD coatings offer a range of benefits that make medical instruments more durable, corrosion-resistant, biocompatible, and aesthetically appealing, ultimately contributing to improved functionality and hygiene in medical settings.

Enhance Your Product with Special Applications!

We specialize in some of the more difficult applications, so if you are looking for a hard-to-find coating, have very difficult parts to coat, or are just looking for technical advice, give us a call. If we can’t do it, we’ll refer you in the right direction.

Instruments Get Specialized Treatment

We realize your instruments are unique. That’s why we work with your engineers to develop the perfect process for your parts. Working with us, you’ll get the following:

- Special process development

- Parts masked per your specs to look as good as possible

- Traceability

- Certified Processing

- Guaranteed Results

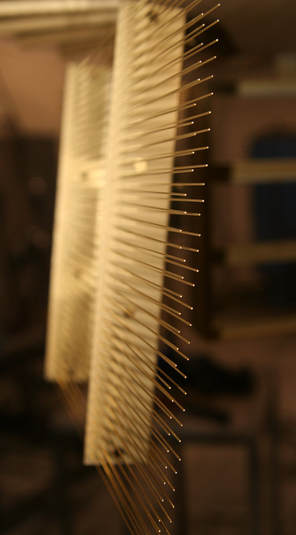

These images show some parts that have been masked on irregular surfaces.