Maximize Molding Profits with TiN & TiCN Coating!

If you are looking to protect your injection mold tooling investment, PVD coating the high-wear components of the mold set is a great way to go. Coating your ejector pins, lifts, cavities and other mold components with titanium nitride (TiN) and titanium carbo-nitride (TiCN) will increase tool life, reduce down-time, eliminate galling and result in more profits for your company.

TiN and TiCN are vacuum-deposited coatings that are very thin (.0001” – .0002”), very hard (>80 Rc) and wear resistant. Because they are very thin, they have minimal effect on tool tolerances, but a huge effect on your bottom line.

Protect Your Injection Mold Investment with PVD Coatings

Injection mold components are extremely expensive. PVD coating them provides the following benefits:

- 5 – 10 x longer life over uncoated mold components.

- Improved release of plastic parts, along with shorter cycle times.

- Eliminate galling between mold components

- Less mold erosion when shooting glass-filled plastics.

- Less corrosion when molding gas-forming plastics.

- Easier mold clean-up, less plasticizer build-up.

- Can be refurbished numerous times so they can last forever.

- More up-time and higher quality parts, all resulting in more profits.

- Up to $100, or more, in benefits for every $1 spent on coatings.

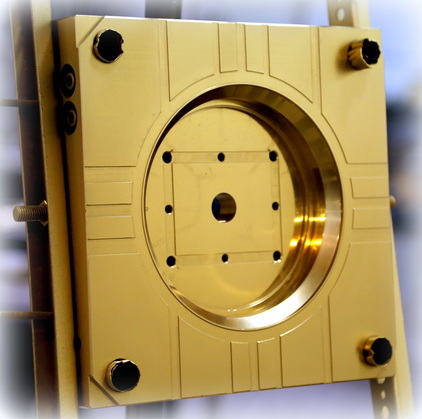

TiN Coated Mold Cavity

Be More Productive!

763-785-9436

Molds Last Forever!

Mold components can essentially last “forever” if stripped and recoated before damage has been done to the base material.

Coating Specifications

Coating Thickness: 0.0001″ – 0.0002″

Hardness:

- TiN – 2600 Hv

- TiCN – 4200 Hv

Application Temp.: 800°F

In abrasive applications, TiCN will usually last 2 – 4x longer than TiN due to it being much harder than TiN.

TiCN Coated Mold Insert