Aluminum Titanium Nitride (AlTiN)

Looking for oxidation resistance? Aluminum titanium nitride (AlTiN) is the coating you need.

The design of our AlTiN coating provides exceptional oxidation resistance and extreme hardness. This coating works well in very demanding cutting tool applications, especially when tools are being pushed to the max.

The design of our AlTiN coating provides exceptional oxidation resistance and extreme hardness. This coating works well in very demanding cutting tool applications, especially when tools are being pushed to the max.

Properties:

- Thickness: .0001″ – .0002″ (2 – 5 microns)

- Hardness: 4000 – 4200 Hv

- Oxidation Resistant (up to 800 – 900°C)

- Deposition Temp. 700° – 800°F

Benefits:

- Provides 2 – 7 x the tool life vs. uncoated tools.

- Good wear & oxidation resistance

- Biocompatible, used on many medical instruments and implantable devices.

Uses:

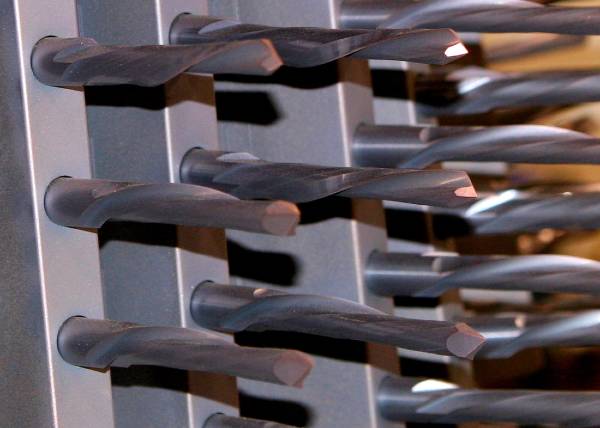

- Cutting Tools

- Die Casting

- High Temp Applications

- Medical Components

- Wear Components

Case History #1

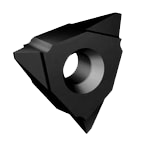

3 Corner Carbide Insert (AlTiN)

- Workpiece: 304 Stainless Steel

- Results: Alpha™ – 2x life over TiN

AlTiN – 3x over Alpha™

With Better Surface Finish

(Speeds/Feeds Constant) - Coating Cost – $2.50 – $4.00 per tool, depending on size.

- Overall performance – 6x better than TiN

What’s the difference between TiAlN and AlTiN?

The designation “TiAlN” is used for Ti-Al nitride coatings where the aluminum content is ≤ 50 atomic percent.

The designation “AlTiN” is used when the aluminum content is > 50 atomic percent.

Our coatings have a high percentage of Al in the film, making it more consistent with being an AlTiN coating, rather than a TiAlN coating.

AlTiN is typically a black, or charcoal black in color, while TiAlN is often a dull brown in color.

When tested head to head, AlTiN usually outperforms TiAlN.